Our Services

Which would best suit your needs and fit your packaging operations?

Customer Service:

Exceptional Service You Can Rely On!

Keeping our customers happy is our main concern and we strive to meet this objective on a continuous, daily basis. We specialize in working hand and hand directly with clients throughout the product development process to ensure brand image while creating efficiencies and cost savings throughout the manufacturing process.

Our sales team has over 45 years of experience in the packaging industry. Our team of packaging professionals and sales are fully knowledgeable of our products and are dedicated to providing our customers with the best information and support available in a timely manner. You will find people working late to get a ‘rush job’ out to a customer who needs something urgently.

shipping costs, or a carton made out of a thicker board grade of corrugated material to provide additional protection, we will give you proper expert guidance for structuring your box according to your application.

shipping costs, or a carton made out of a thicker board grade of corrugated material to provide additional protection, we will give you proper expert guidance for structuring your box according to your application.

There are a number of different factors that go into making corrugated boxes, and it’s one of the reasons why they’re so customizable. The next aspect you’ll want to look at is the type of board. There are four types of boards that can be used for corrugated boxes. The most common types used are single and double walls in various C, B, E, and F flutes.

Die cut boxes, Telescope Boxes, Folders, Rigid (or Bliss) Boxes, Self-Erecting Boxes, and Interior Forms.

Die cut boxes, Telescope Boxes, Folders, Rigid (or Bliss) Boxes, Self-Erecting Boxes, and Interior Forms.

Whether a commodity placed in a supermarket attracts customers, to a large extent, is dependent on whether it is easy to carry. Especially for some goods that are not easily carried limited by their shape, weight, or size, thus the portability of the packaging structure is particularly important.

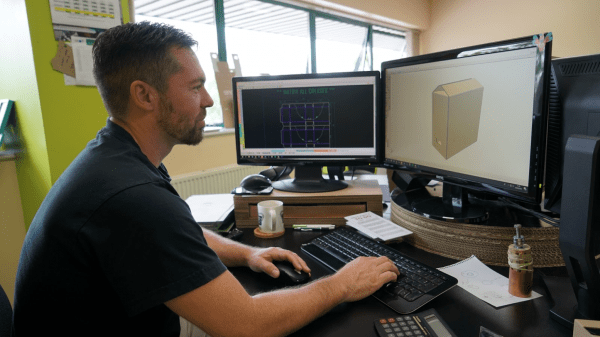

We use CAD software to create graphics and specs, which then become dies for your custom box. The most important part of this process is communication. We want your input to create the best packaging for your products. We focus on improving the user experience, enhancing functionality, and maximizing manufacturing efficiencies from concept to completion.

Design:

BC BOX design process starts with your brand. Whether your customers are receiving a package in the mail or making a purchase in a store, your product packaging is an opportunity to make a lasting impression that keeps customers coming back.

You may provide us with detailed graphics and specifications for your packaging requirements or leave it to our team to create the most innovative and efficient design for your packaging needs. Our business model is designed to make packaging easy for our customers. We can find it, design it, source it, make it, ship it, store it, and more.

Quality control may also involve testing samples of printing on the boards to assure accuracy for the final product.

Quality control may also involve testing samples of printing on the boards to assure accuracy for the final product.